Experimental Fluid

Dynamics Laboratory

Facilities

Flow Facilities

Prof. Ekmekci's research group has three main experimental facilities where tests are conducted: a large-recirculating water tunnel for aerodynamic tests, an anechoic wind tunnel for aerodynamic and aeroacoustic tests, and an anechoic room for acoustic tests.

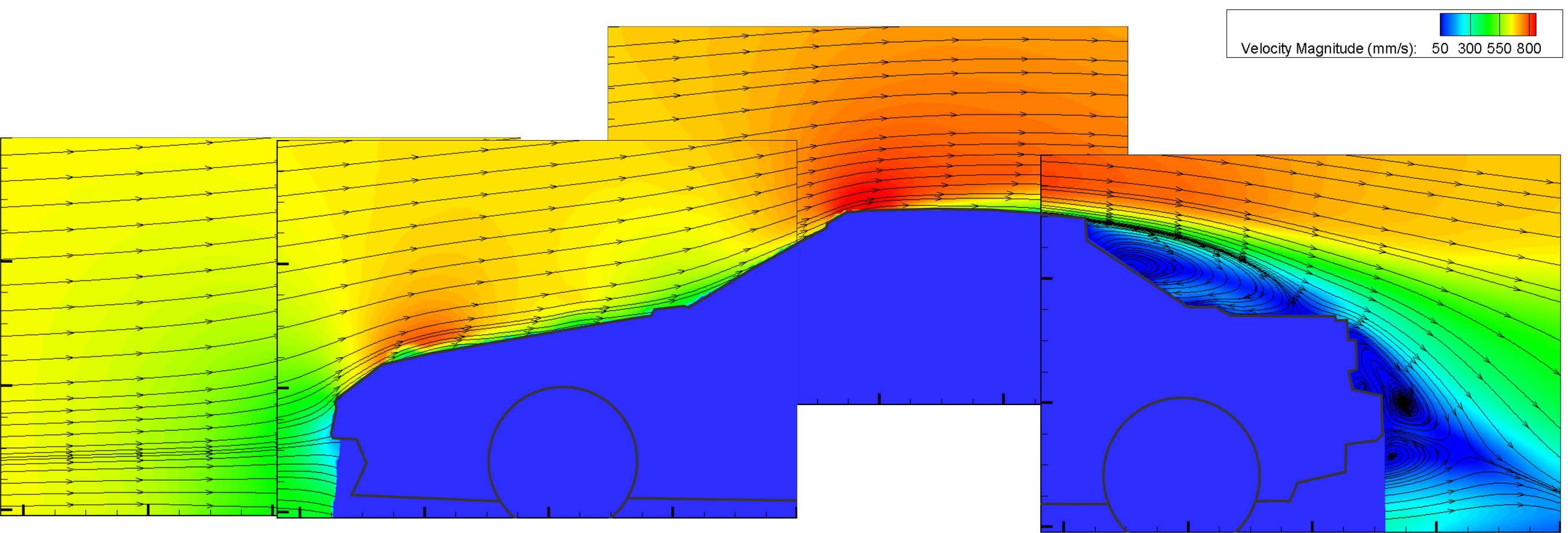

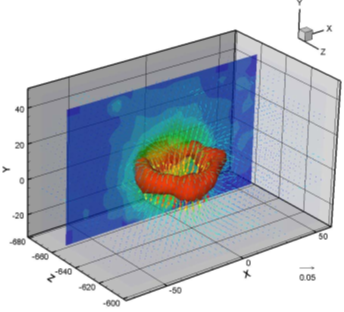

1. Water Tunnel

This is a recirculating flow facility, continuously providing a uniform flow along its 5-m long test section. The walls of the test section are made of Plexiglas material to allow optical access to the flow. This facility can operate in free-surface mode (with no top covers) or as a closed tunnel (using top covers). It is known that compared to a wind tunnel flow facility, the water flow facilities have the advantage of slowing down the flow dynamics are thereby enabling the capture and time- resolved analysis of highly unsteady flow behavior. This facility is therefore used to simulate the flow fields around scaled models of various bodies, including cylinders, landing gears, automobiles, Ahmed bodies, micro air vehicles, etc.

The technical details of this facility can be summarized as follows:

| Tunnel Type: Recirculating Water Tunnel

Facility Modes: (1) Free-surface channel (removing the top covers) (2) Closed tunnel mode (using top covers) Test Section Details: 5 m (L), 0.610 m (W) , 0.762 m (H) (in free-surface mode) & 0.686 m (H) (in closed tunnel mode) |

Speed Range:

0.03 m/s - 0.8 m/s Maximum Reynolds Number: Re = 880,000 per meter @ T = 25 C (Water temperature is controllable using a thermocouple and a tankless water heater) Turbulence Level: < 0.4% @ 0 - 0.66 m/s, < 1.3% @ 0.66 m/s - 0.8 m/s |

Water tunnel facility

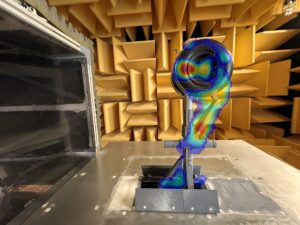

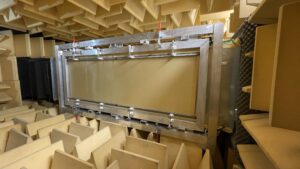

2. UTIAS Hybrid Anechoic Wind Tunnel

This facility is suitable to conduct aeroacoustic and aerodynamic measurements. Its test section is interchangeable between three operation modes: (1) an open jet test section, (2) hard-walled test section, and (3) test section with tensioned Kevlar side walls. The test section is enclosed within an anechoic chamber, which provides a suitable environment for a broad spectrum of aeroacoustic measurements in open-jet and Kevlar-walled tunnel configurations. The technical details of this facility can be summarized as follows:

| Wind tunnel modes:

(1) Open jet enclosed within an anechoic chamber, (2) Tensioned-Kevlar walled test section within an anechoic chamber, (3) Hard-walled test section Speed Range: 10 m/s - 75 m/s (in open-jet configuration) 10 m/s - 60 m/s (in Kevlar walled configuration) 10 m/s 60 m/s (in hard-walled configuration) Cross-Section: 0.6 m (H), 0.6 m (W) (in open-jet configuration) 0.83 m (H), 0.83 m (W) (in Kevlar walled configuration) 0.83 m (H), 0.83 m (W) (in hard-walled configuration) Turbulence Level: |

Anechoic chamber

Outer dimensions: 6 m (W), 6 m (L), 3 m (H). Inner dimensions: 4.9 m (W), 4.9 m (L), 1.8 m (H) Wall treatment: Triangular-shaped acoustic foam wedges Cutoff frequency: 160 Hz

|

|

|

|

|

| Anechoic wind tunnel in open-jet configuration | Anechoic wind tunnel with tensioned-Kevlar walled test section | Hard-walled wind tunnel test section with the 30P30N model inside it |

3. Anechoic Room

This facility is used to conduct noise measurements in no-flow (quiescent) conditions.

The technical details of this facility can be summarized as follows:

|

Facility: Anechoic Room Anechoic Room Dimensions: 2.83 m, 3.97 m, 2.07 m Wall Treatment: Triangular-shaped acoustic wedges Cutoff frequency: 150 Hz |

|